Tig welding and tungsten metal work so well when welding mild steel because the tungsten keeps the arc with a consistent temperature of 11 000 degrees f.

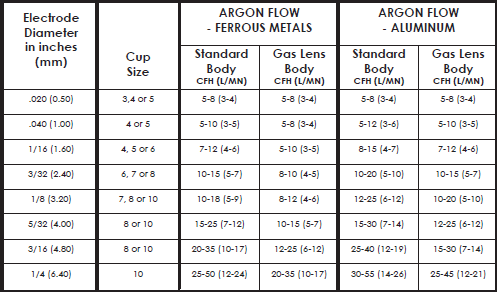

Electrode size tig weld 20 gauge sheet metal.

Electrode size common tungsten electrode sizes range from 3 32 to 1 1 4 of an inch.

These electrodes are used mainly for specialty ac welding such as thin gauge aluminum and material less than 0 060 inch and dc welding either electrode negative or straight polarity on carbon steel.

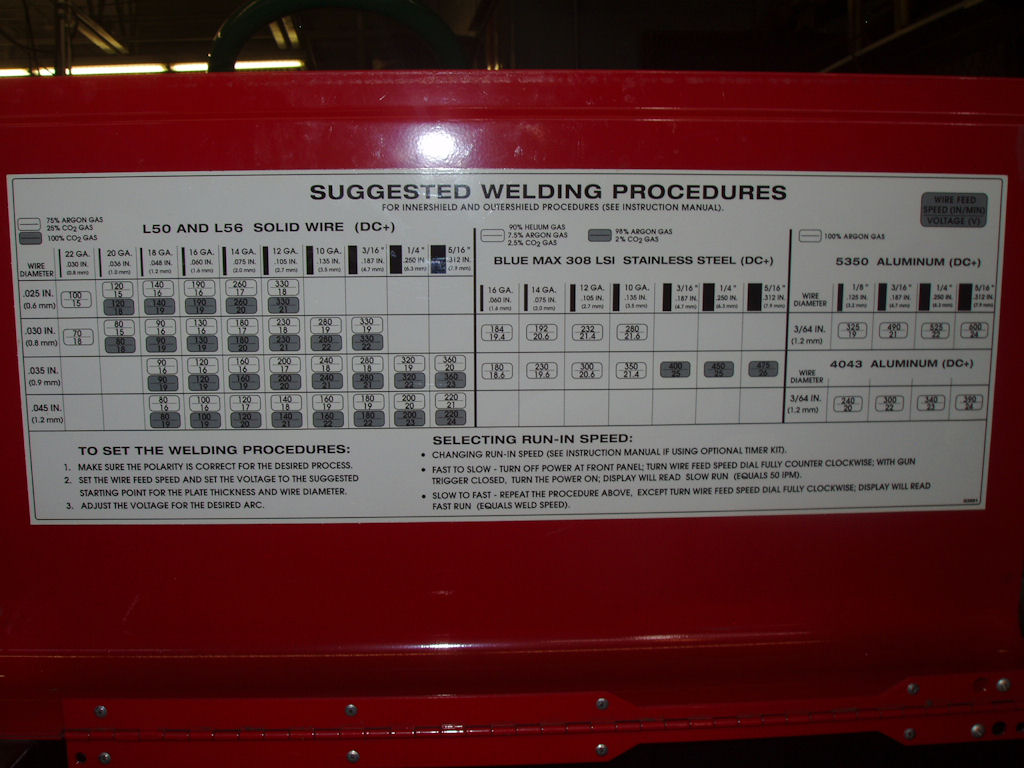

When the material is 18 gauge and thicker you may be able to use a 030 inch wire.

To ensure the integrity of the weld the filler metal and base material should be chemically compatible and possess similar mechanical properties.

The tig process relies on tungsten s hardness and high temperature resistance to carry the welding current to the arc as it has the highest melting point of any metal 3 410 degrees celsius.

Tig welding parametres table.

Compared with other electrodes thoriated electrodes deposit less tungsten into the weld puddle so they cause less weld contamination.

Electrode solid wire and cored wire and can be used to weld types 402 410 414 and 420 steels.

Selecting the right size depends on variables such as polarity amperage joint size and base metal thickness.

A bad low quality earth or a low voltage supply can seriously lower the maximum welding capabilities of your welder.

I am new to welding and am trying to butt weld 22 guage mild steel sheet together i am using a miller dynasty 200 dx tig tried 1 8 ceriated electrode 3 32 lath electrode with argon flow at 20 cfh settings are dc with current ranging from 10 to 50 amps the butt joints are fit fairly tight but you can see light through the gap my problem is the edges of the steel melt away and open holes almost.

To weld mild steel choose an american welding society classification wire such as er70s 6 which has a weld puddle that wets out nicely.

In resistance welding lower current can.

With over 0 20 c often require a post weld heat treatment to soften and toughen the weld.

It s recommended to use a 023 or 024 inch wire for most light gauge sheet metal work.

Joint as rapidly as in carbon steel.

In a situation when a welder needs to make a butt weld on a 20 gauge panel and the parts are not able to touch each other not even for even 1 16 inches you will create a gap that is not capable of being absorbed by the heat.

Fit up and joint design.

Sheet metal welding demands really tight fit ups.