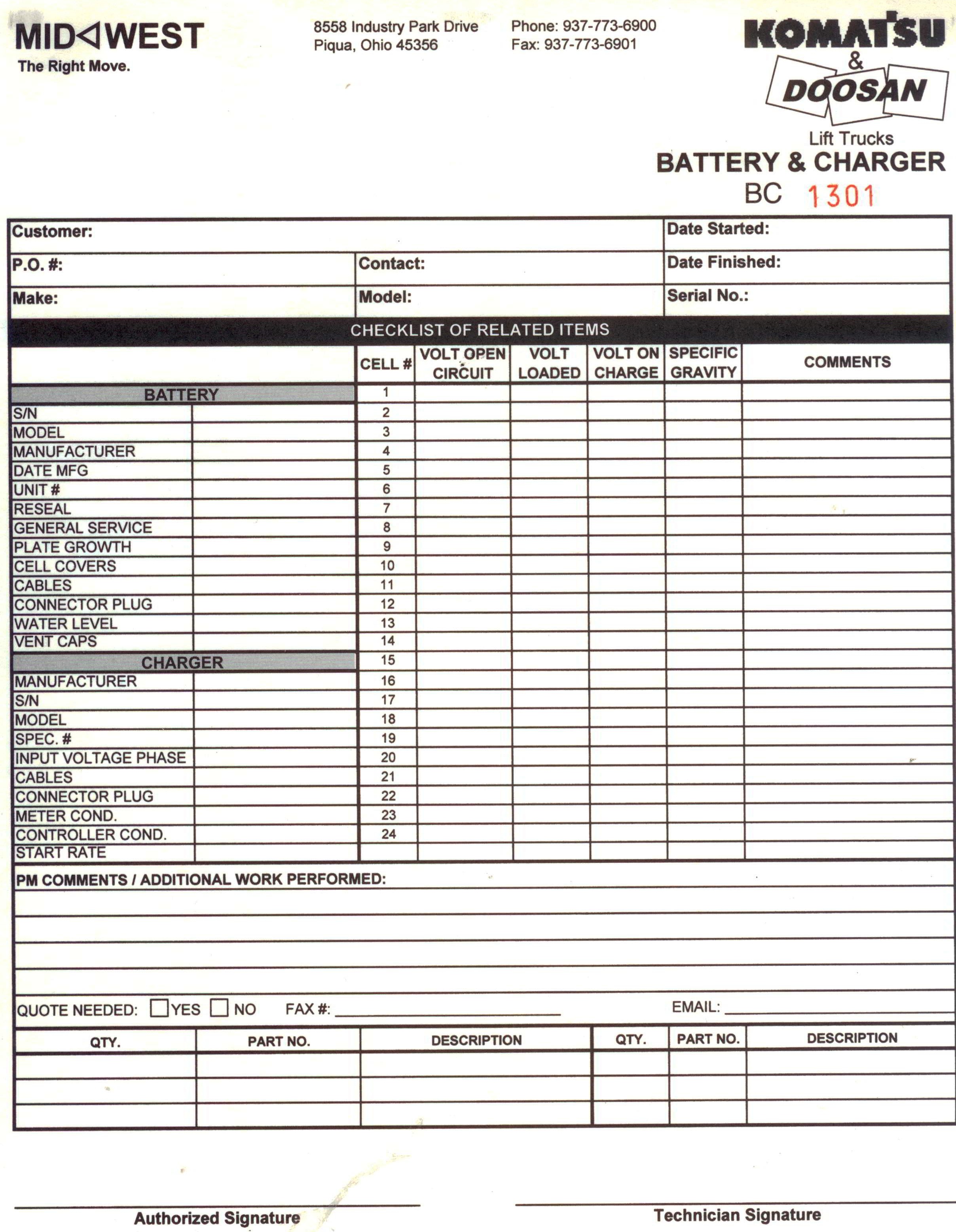

No matter who provides the service though maintaining batteries is a crucial part of running a profitable electric forklift fleet.

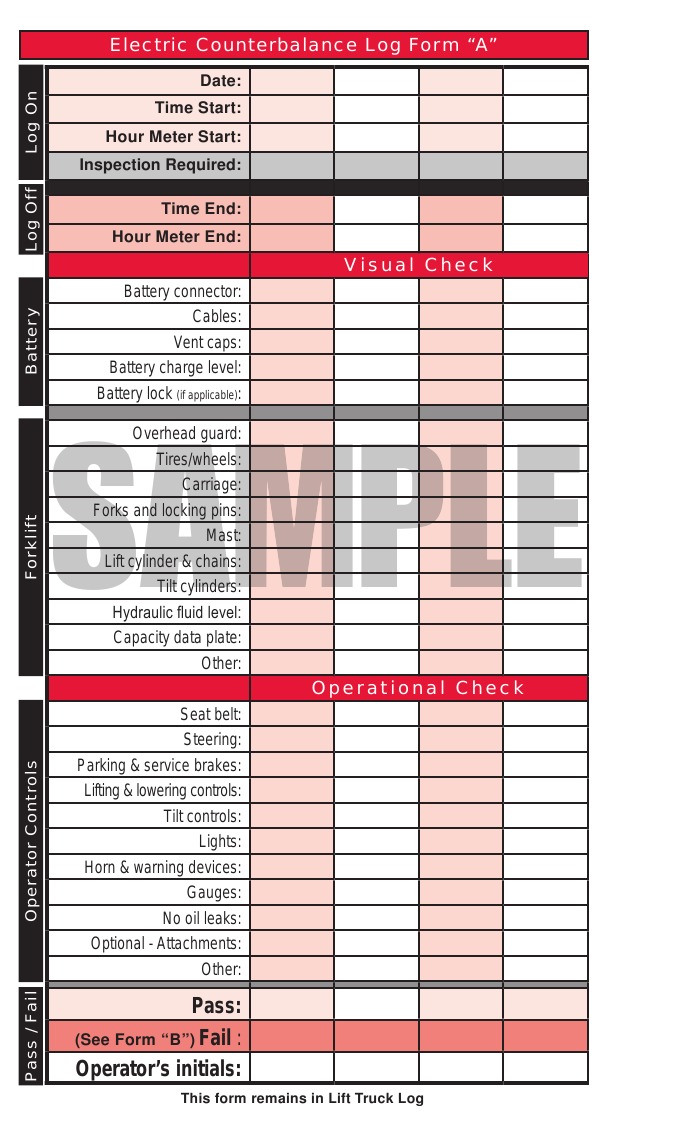

Electric forklift battery maintenance checklist.

Check fluid levels forklift batteries need to have the right amount of water to work at optimum capacity.

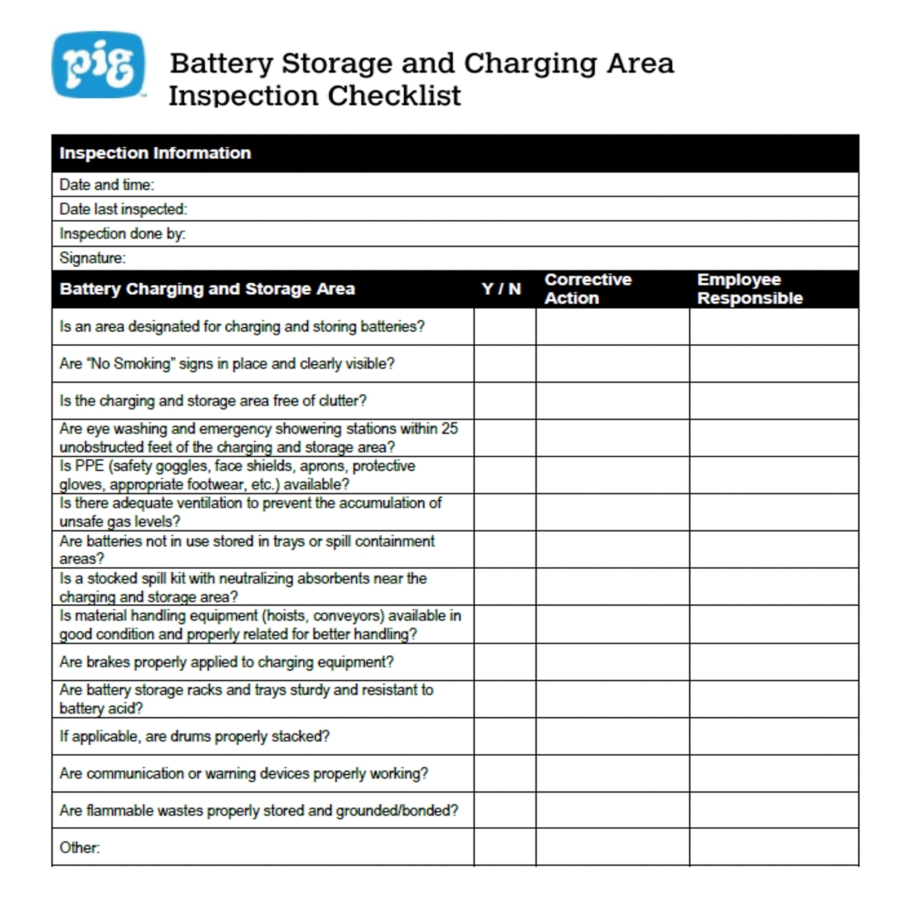

The occupational safety and health administration osha standard 29 cfr 1910 178 g lays out the safety requirements for forklift battery charging areas.

Battery charging should be done in a place designated for that purpose only.

Your investment in electric lift trucks and industrial batteries needs to be protected in order to maximize the benefits that they have to offer.

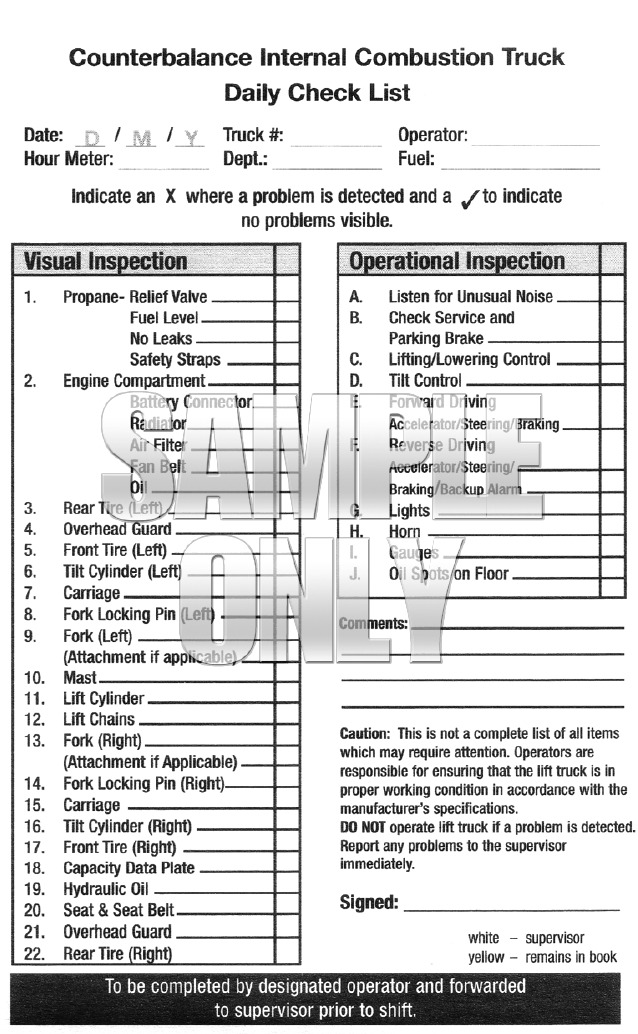

Depending on usage and application some forklift users may need to increase or decrease maintenance intervals.

Don t allow your forklift batteries or forklift battery chargers to drag down the rewards that properly maintained equipment.

The goal of this article is to help extend the life of your batteries and improve the performance and life span of your lift truck by educating forklift operators on some of the basics of electric forklift battery maintenance for an electric forklift making sure your team is aware of the maintenance plan is critical for the longevity of your pallet jacks and lift trucks.

Forklift battery repairs happen but it is our goal to keep that to a minimum.

Many batteries need equalization approximately each five to ten charging cycles but be sure to check the maintenance specifications for a battery before initiating the process.

This battery maintenance checklist can ensure that your workers or you have performed all of the necessary and basic checks required to perform battery maintenance safely.